Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The study found that the compressive strength of limestone is closely related to the service life of the hammer. The higher the compressive strength, the worse the friability and the shorter the service life of the hammer. In addition, the silicon content in the limestone chemical composition has a great influence on the service life of the hammer head. The silicon has a strong abrasiveness to the hammer head, which causes the hammer head to wear rapidly. In general, the higher the silicon content, the shorter the life of the hammer.

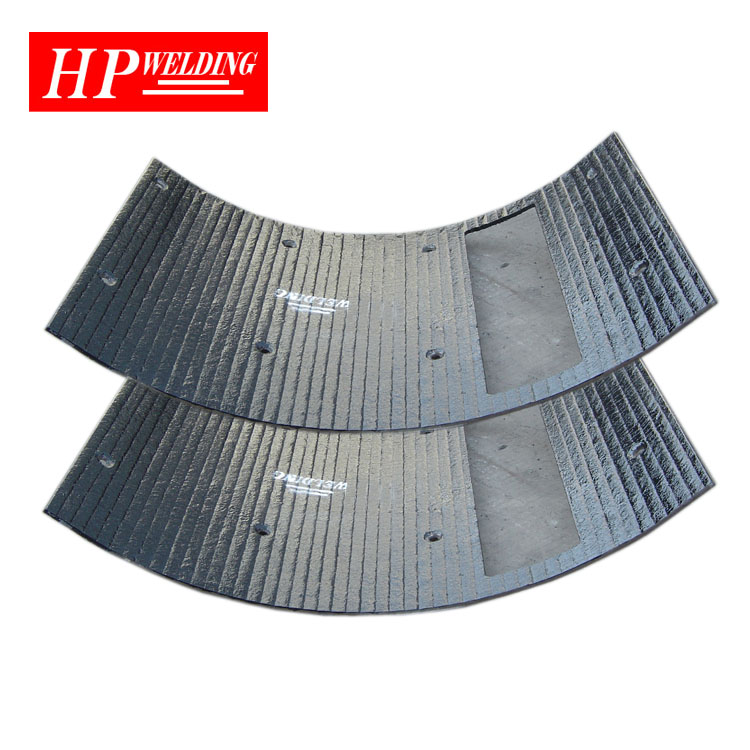

In recent years, with the continuous emergence of new technology for crushing hammers in China, ultra-high manganese steel hammers and alloy wear-resistant hammers have emerged. The so-called alloy wear resistance is in the working part of the crusher hammer, inlaid with hard alloy rods or alloy blocks. Since the hardness of the inlaid alloy can reach above HRc56, the anti-wear performance of the crusher hammer head is improved.

At present, China's cement industry wear parts need to be upgraded. The alloy wear-resistant hammer head, high-chromium alloy plate hammer, vertical grinding roller and so on, which are embedded with hard alloy rods, have become the first choice for upgrading. For example, a wide range of crusher hammers. At present, the best use of cement companies is the “Dajinya” super hammerhead with inlaid carbide rods produced by Zhengzhou Dingsheng. This hammerhead is hard on the ultra-high manganese steel substrate. The alloy rod can be used not only in the case where the lime content of the limestone is normal (≤ 2%), but also in the case where the lime content of the limestone is high.

Moreover, the hammer is safe to use. When crushing limestone raw materials of the same quality, its service life is significantly longer than that of ultra-high manganese steel or high manganese steel. It is worth mentioning that the alloy is wear-resistant. Hammerhead once set a record of 320 tons of broken materials in Jiangxia East Cement and a long service life of 17 months. It was praised by many large cement groups such as Shanshui Cement and Tianrui Cement.

Of course, the service life of the crusher hammer is not only determined by its material and production process. The cement manufacturer only understands the limestone quality index, strictly implements the mine management regulations, selects the most suitable hammerhead, and scientifically performs the crusher operation and overhaul. In this way, the efficient and rational use of the crusher hammer can be guaranteed from all links, thus smearing a strong stroke for the rapid development of China's cement industry.

June 01, 2023

October 14, 2022

October 14, 2022

この仕入先にメール

June 01, 2023

October 14, 2022

October 14, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.