モデル: HP-RL

ブランド: HPプレート

原産地: 中国

処理サービス: 成形, 切断

Specified Size: Make To Order

包装: 鉄骨または木製ケース

生産高: 500 Ton per year

輸送方法: Ocean,Land,Air,Express,Others

原産地: 中国

についてのサポート: 500 tons per year

認証 : ISO9001: 2015

HSコード: 4016999090

ポート: Tianjin,Shanghai,Qingdao

お支払い方法の種類: L/C,T/T,D/P,Paypal

インコタームズ: FOB,CFR,CIF,EXW,FCA,FAS,DAF,DES,CPT,CIP,DEQ,DDP,DDU

ラバーライナーは、主にAGミル、SAGミル、ボールミル、バーミルなど、鉱業、セメント、化学工業、建材、冶金などの分野で使用されています。耐摩耗性ゴムライナーの利点は次のとおりです...

1.耐衝撃性、耐食性、耐摩耗性、耐酸性および耐アルカリ性2.軽量3.低ノイズ

ラバーライナープレート、セメントボールミルライナープレート、耐摩耗性ラバーライナー、ボールミルスペアパーツ、耐摩耗性ラバーライナーは定期的にお客様に提供されています。

主な製品は、ラバーライナー、セメントボールミルライナープレート、プラスチックシール、ポリウレタンアクセサリー、高圧ゴムホース、コンベヤーベルト、コンベヤーデザインなどのボールミルスペアパーツです。シェルリフターバーラバーライナーは、特にセメントボールミル用です。優れた品質を備えた当社の耐摩耗性ゴムライナーは、多くの国の多くのお客様に広く選択されています。

ゴム製品の主な仕様:

| Performance Index |

Unit |

Standard |

|

Tensile strength |

Mpa |

17 |

|

Elongation |

% |

420 |

|

Permanent Deformation |

% |

10 |

|

300% Tensile Strength |

Mpa |

11 |

|

Impact Elasticity |

% |

45 |

|

Wear Reduction |

cm³/1.61km |

0.15 |

|

Shore (a) Hardness |

65±5 |

|

|

Aging Coefficient (70℃*48h) |

0.8 |

Ball Mill Liner components:

Our ball mill liners solutions can be fitted with lifter bars, shell plates and head plates. We utilise Hardox wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance.

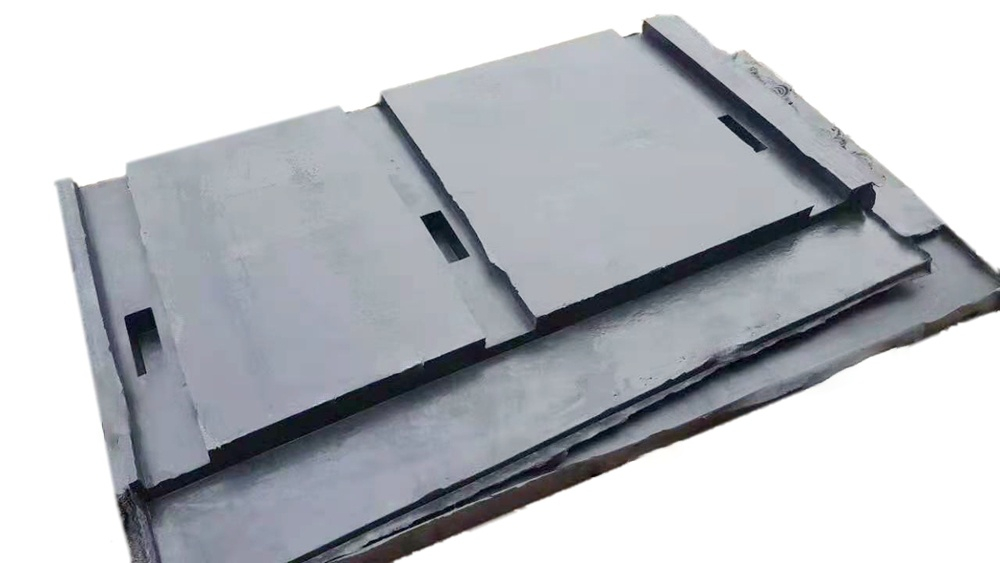

Shell Plates

Shell plate thickness can vary, which helps both in balancing mill capacity as well as extending ball mill liner life. For arduous milling applications, or where drilling patterns produce shell plates that are too wide, thus exposed to high wear, shell plates with Hardox strips can be utilised.

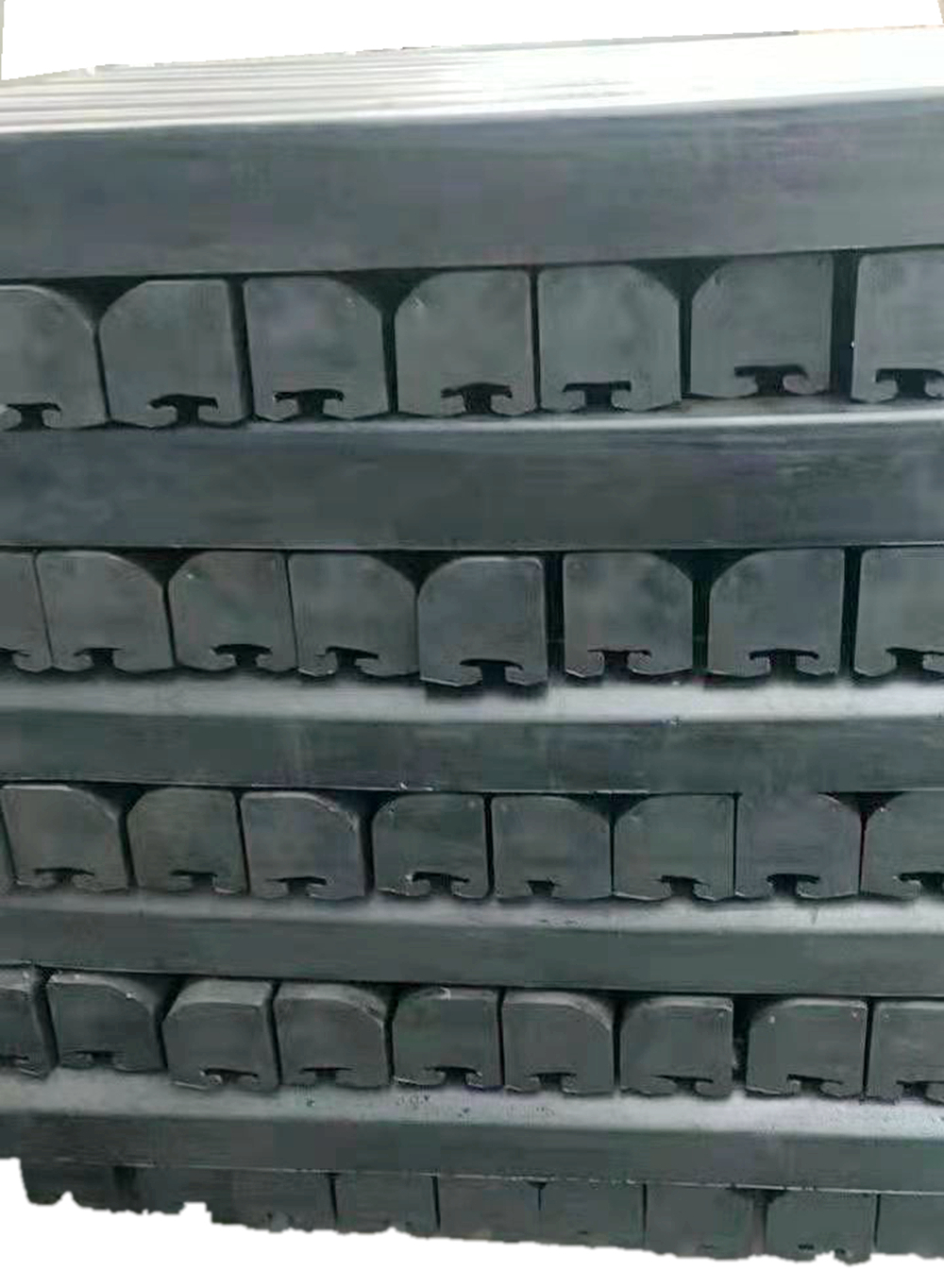

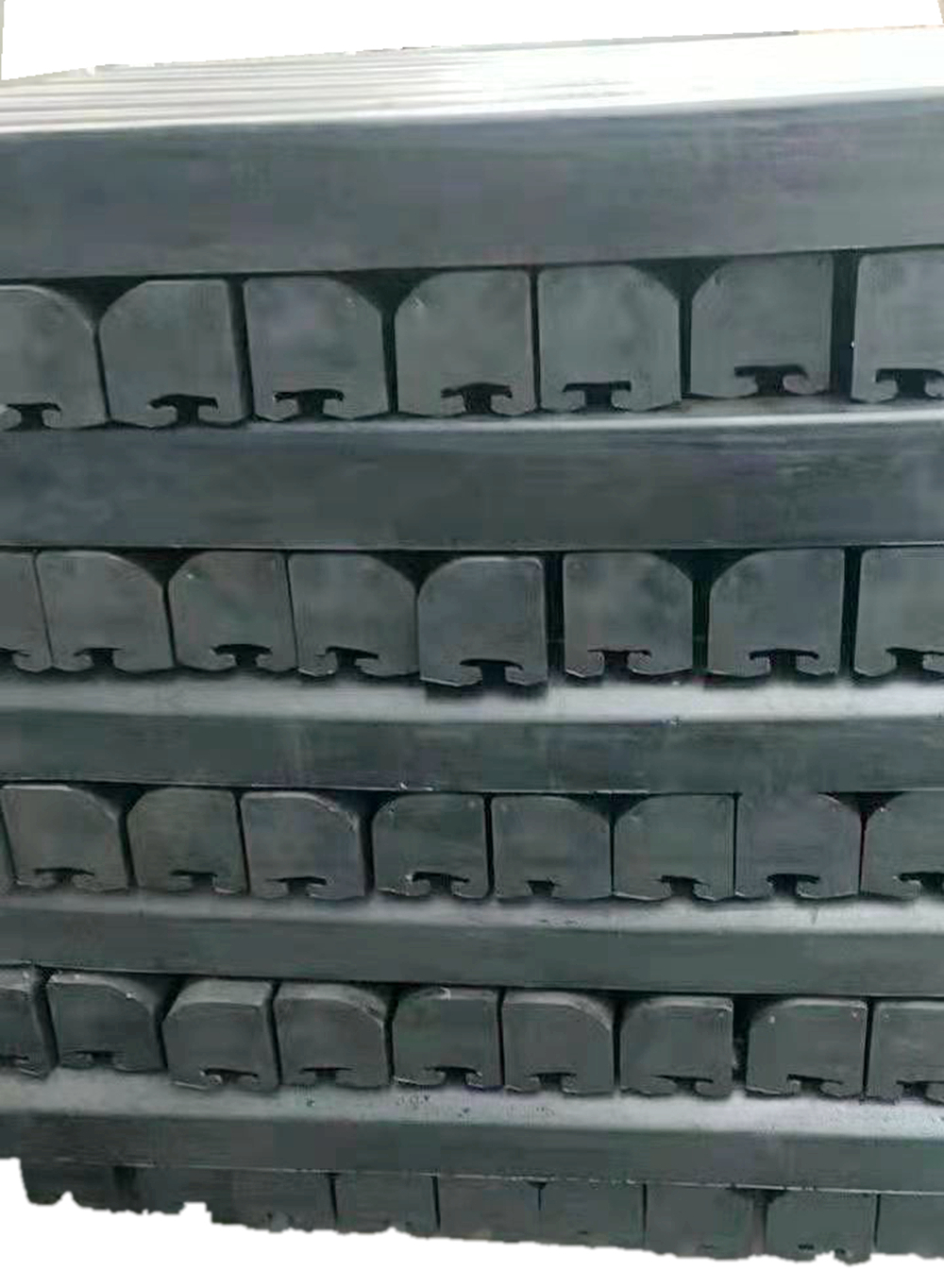

Lifter Bars

Available in a range of profiles and dimensions, lifter bars increase the efficiency of the milling operation by maximising the agitation of the ore. The impact and abrasion resistance of these bars is maximised by Hardox steel along the leadings edges of these components. With a high-quality attachment system, lifter bars are easy to install to the ball mill liner.

Head Plates

We custom-design head plates according to each ball mill to ensure maximum performance and lifespan. Most commonly, our head plates are built from high-quality, specially-formulated rubber. In arduous ball mill applications, Hardox strips can be fitted to the head plates to increase their operational life.

Grate Plates

Grate plates are available in a range of aperture sizes and configurations. Internal frames are designed for different mill loads, and it is possible to use semi-overflow designs in order to control the pulp level in the mill. Different options for extending plate life exist as required by your application, such as built-in lifter bars.

Pulp Lifters

Manufactured with a rubber-lined fabricated steel base, our pulp lifters use high-quality designs that ensure a correct volumetric flow of the pulp. Rubber wear plates designed to be bolted onto the high-wear areas of the ball mill liner improve the performance life of your mill.

Central Cones

These components assist in the controlled discharge of the material, maintaining mill capacity across the operation. Cones are provided in segments, which are then assembled inside the mill. This enables easier handling and manageability.

Trunnion and Bell Mouth Liners

Manufactured with a fabricated steel base that is then rubber lined. Loose steel-reinforced rubber liners are also used in larger trunnions.

Filling and Support Segments

Extend the wear liner to the corners of your ball mill and scrubber, enabling a clean, smooth lining across the ball mill liner.

Key Specifications Of Rubber Product:

Unit

Standard

Tensile strength

Mpa

17

Elongation

%

420

Permanent Deformation

%

10

300% Tensile Strength

Mpa

11

Impact Elasticity

%

45

Wear Reduction

cm³/1.61km

0.15

Shore (a) Hardness

65±5

Aging Coefficient (70℃*48h)

0.8

Packing & Delivery

Packing Way: By Wooden Case, By Steel Belt, By Steel Pallet

Delivery Time: 4 weeks after order confirmation or to discuss

Company Information

We are specialized in designing and manufacturing wear resistant products including anti-abrasion rubber lining, polyurethane lining, wear resistant steel products, ceramic liner, conveyor accessories, etc. Our products are widely used in bulk material handling industries including coal mine, steel plant, power generation, cement plant, metallurgy, chemical and other fields.

HP Wear Solution Products Show Case:

HP Factory Laboratory

Performance Index

Q1:カスタマイズは利用できますか?

A:お客様のリクエストに応じてカスタマイズをサポートします。

Q2:配達時間はどのくらいですか?

A:3〜4週間。緊急順序が必要な場合、主要な原材料在庫があり、必要に応じて優先事項が与えられます。

Q3:工場にアクセスできますか?

A:はい、私たちを訪問していただけます。利用可能な場合は、旅程を共有してください。

Q4:製品の品質管理は何ですか。

A:すべての製品は、配達前に厳密に検査されます

Q5:サンプルは無料ですか?

A:はい、無料のサンプルが利用可能であるか、議論されます。

Q6:発注書を進めるにはどのような情報が必要ですか?

A:技術的な図面が詳細に提供されれば、それは私たちを非常に支持します。