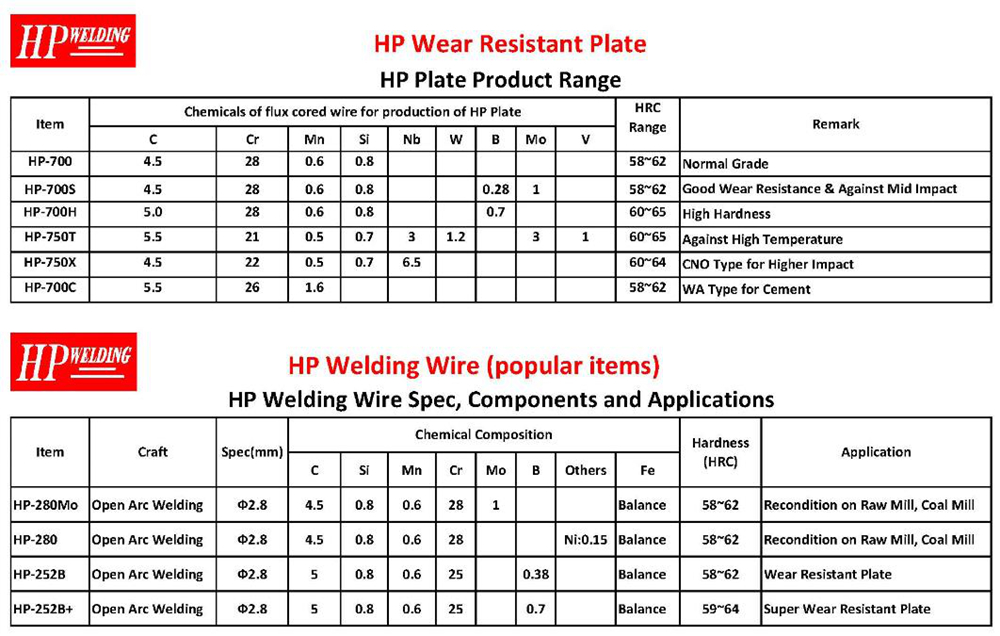

モデル: HP-WR

ブランド: HPプレート、HP溶接

原産地: 中国

Make To Order: Comply To The Drawings By Customer

包装: スチールフレームと木材ケース

生産高: anual capacity 5000 tons

輸送方法: Ocean,Land,Air

原産地: 中国

についてのサポート: 500 tons per year

認証 : ISO9001: 2015

HSコード: 8474900000

ポート: Shanghai,Qingdao,Shenzhen

お支払い方法の種類: L/C,T/T,D/P,Paypal

インコタームズ: FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,DDP,DDU

In cement plant, the raw material is uniformly fed through the feeder at the bottom of the hopper, and then raised to a suitable height by the bucket elevator, and then sent to the mill through the feeding pipe for grinding, and the ground material enters the powder classifier and is produced by the hot air furnace. Hot air, at the same time dry and grade the material, the unqualified material is poured into the grinding, the qualified fine powder is sent to the powder collector, and then transported to storage through the conveyor.

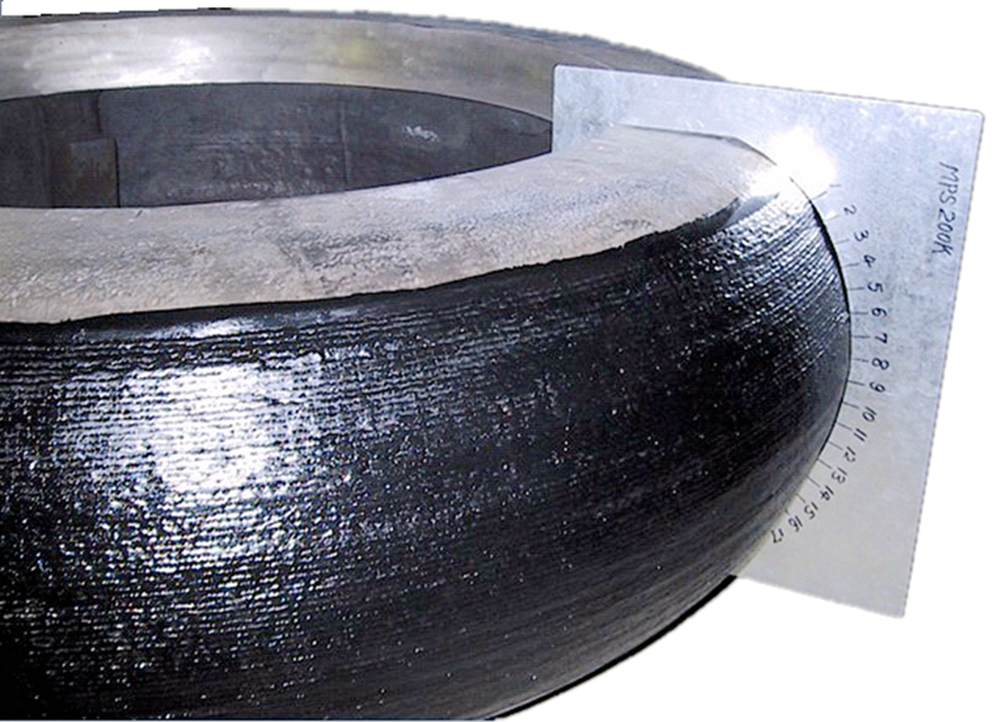

Welding Recondition like Grinding Table Liner Welding Recondition is the best way to reduce cost through increase working life of your equipment.

Take Cement Mill Grinding Table Welding Rebuild for example, the Coal Vertical Roll Mill (VRM) is an air scanning, medium speed vertical mill with an integrated classifier. It pulverizes coal by applying a hydraulically loaded grinding pressure through three grinding rolls to a rotating bed of coal. The grinding pressure can be adjusted to take into account changes in coal grindability and desired product fineness.

Wear Resistant Casting Spare Parts Welding Rebuild is also workable to us.

Advantage Feature* Longer use time and lower maintenance costs

* Optimal production efficiency

* Save costs

* Customized product

* 環境を守ること

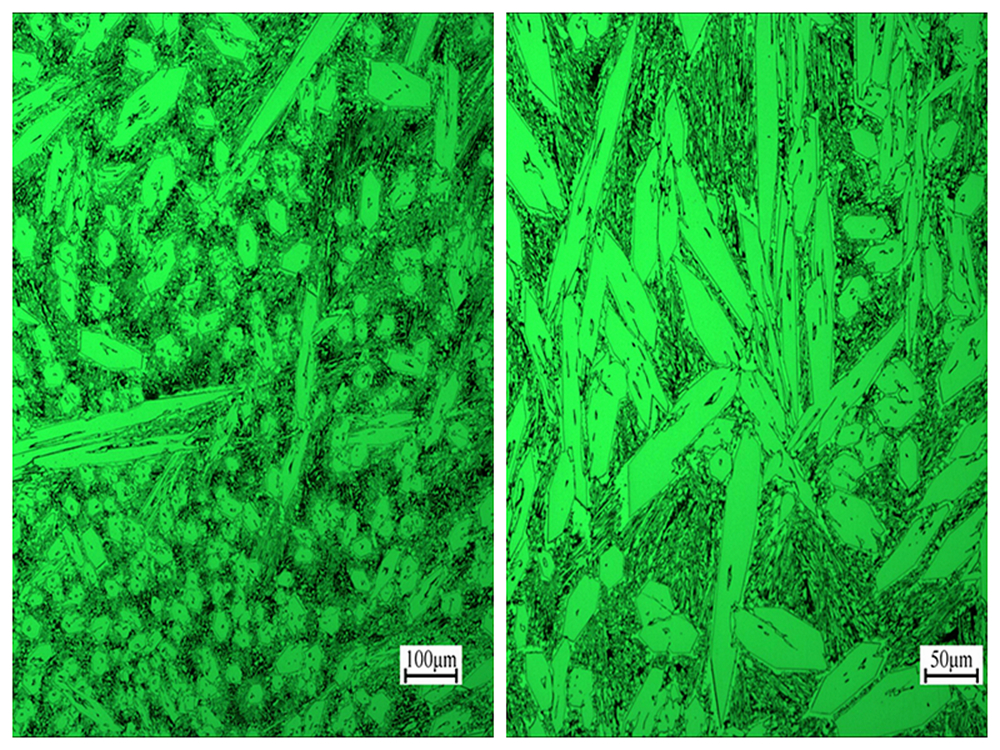

Metallographic Pictures of Tungsten Carbide Overlay By Plasma Transfer Welding

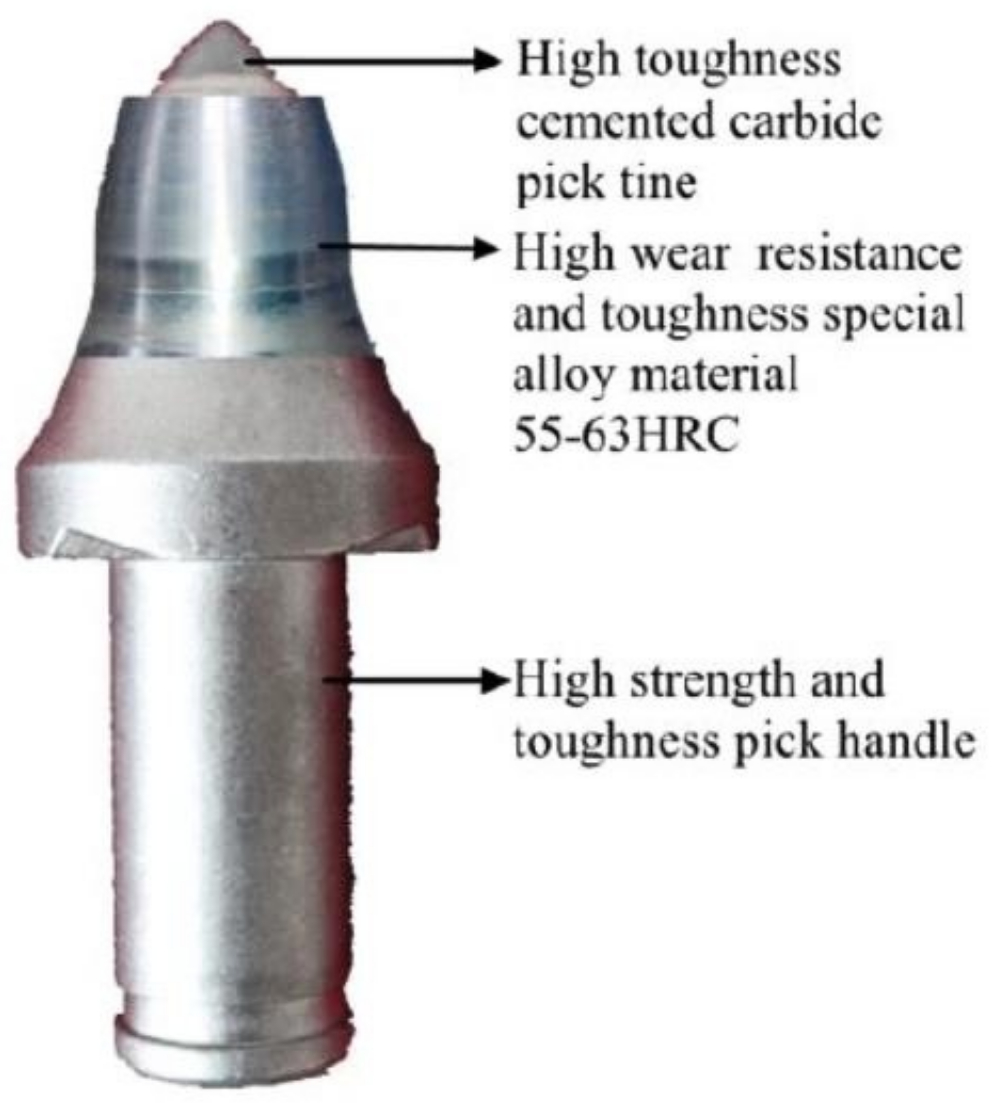

HP 750W products are developed for extremely abrasive applications and both the prime carbide and the matrix are very hard to be against abrasion. This grade is made from spherical tungsten carbide dispersed in NiCrBSi matrix by Plasma Transferred Arc Weld (PTAW) process. The tungsten carbide is 70-75 wt % and the particle size is in the range of 60-325 mesh (44-250 micron) with hardness HV 2700- 2900. The bulk hardness of NiCrBSi matrix is HRC 60-70.

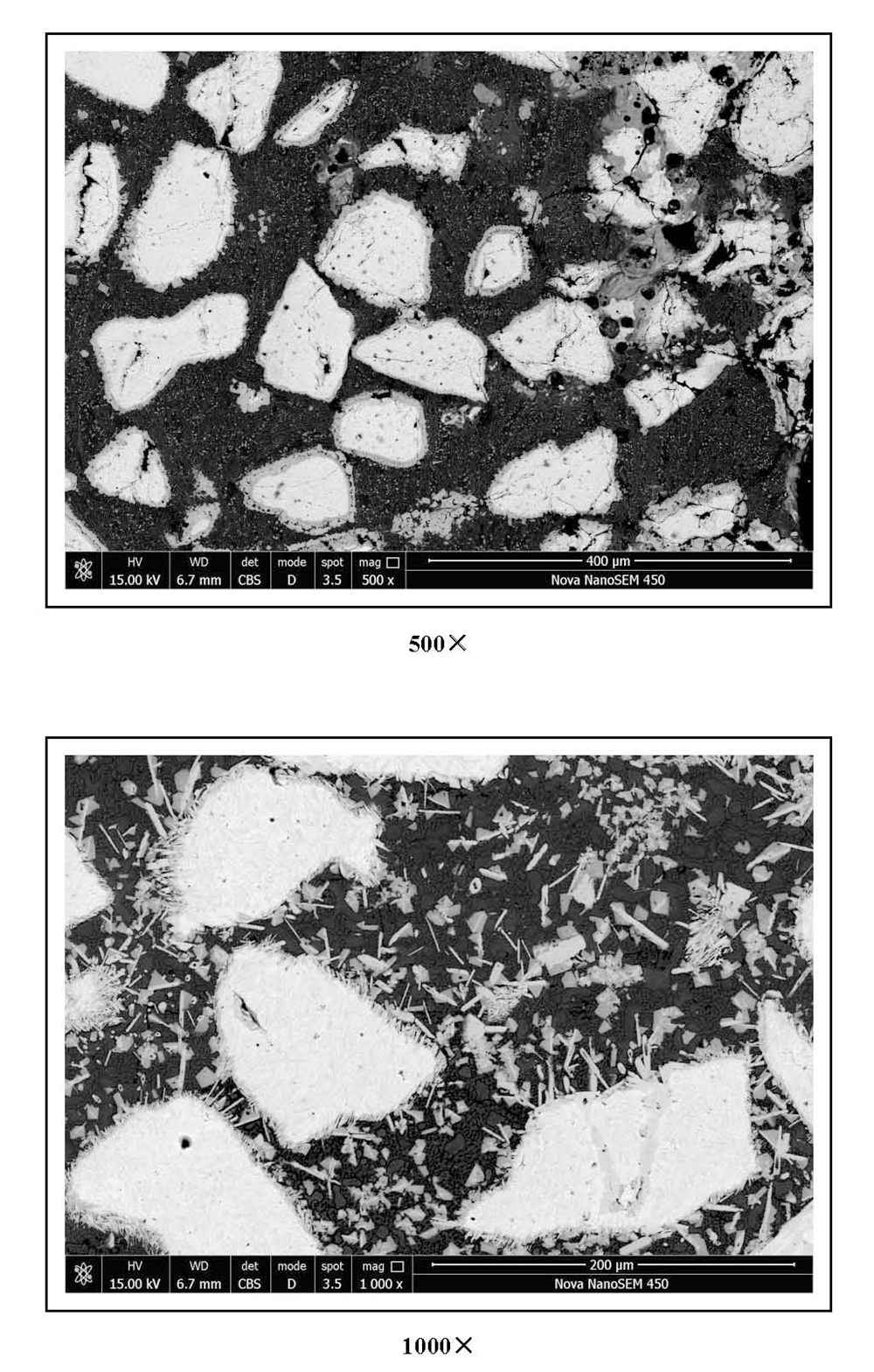

Metallographic Pictures of Chromium Carbide Overlay By Open Arc Welding

The v ertical Mill spare parts_Rollers and Grinding Table Liners which are welding rebuilt by us have unique quenching properties through HP's independently designed wear resistant treatment process. The product not only has good wear resistance and high impact load, but also improves the grinding efficiency and increases the hourly capacity of the machine.

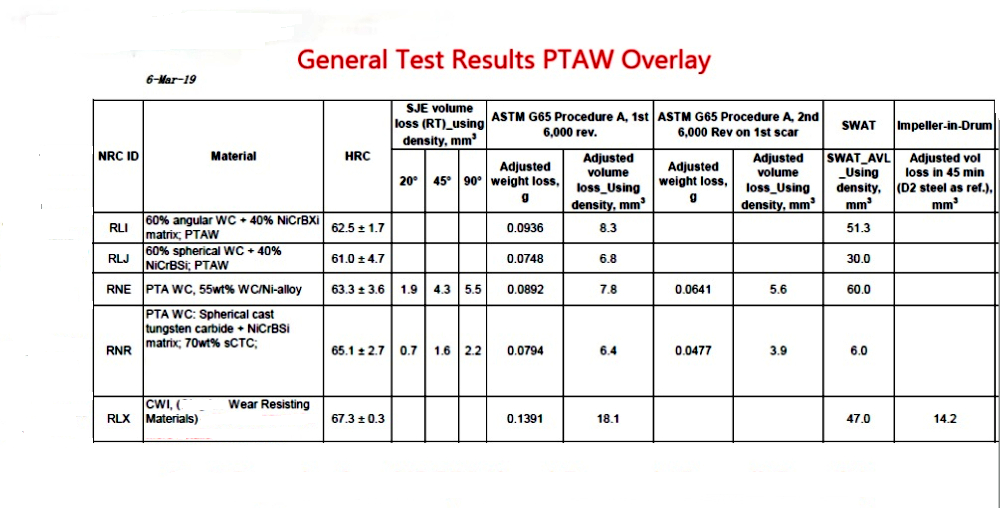

Laboratory Equipments Testing On Welding Rebuilt Product

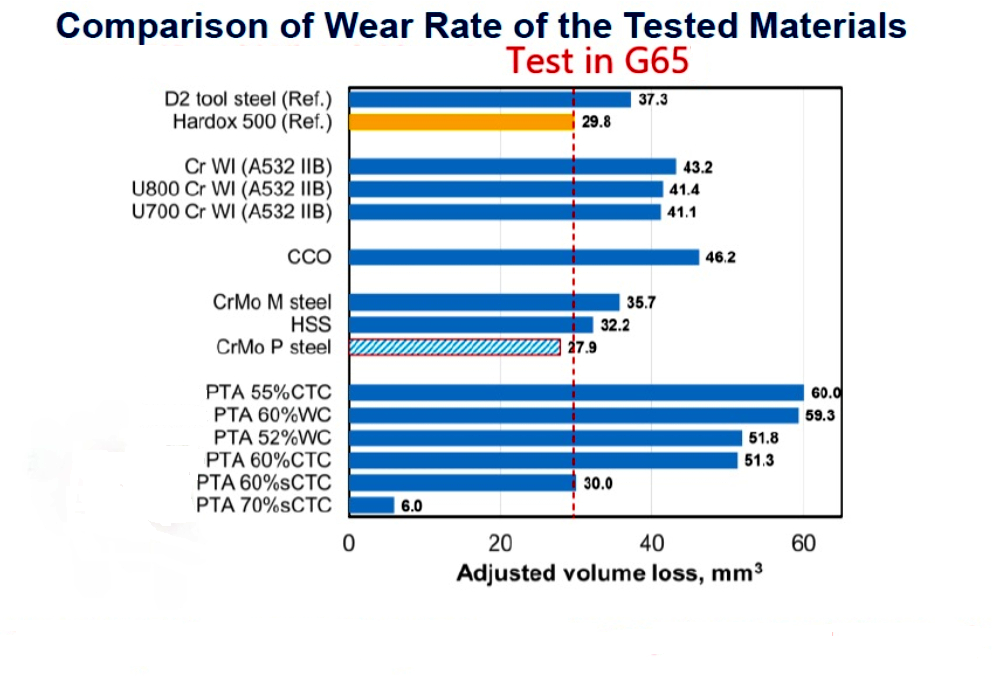

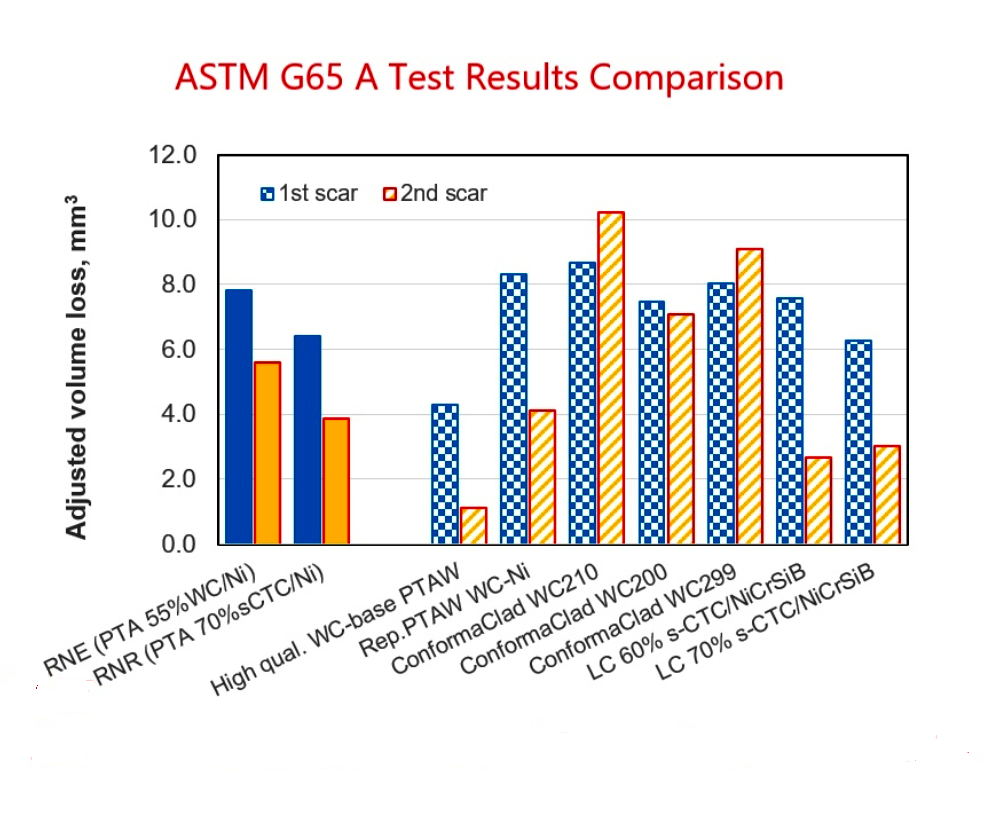

Test Reports On PTAW Products:

梱包と配達

Packing Way: By Steel Frame or Wooden Case

Delivery Time: 30 days or to discuss

FAQ On HP Welding Rebuilt Products

Question 1: What should be taken before welding rebuild?

Answer: Dye penetrate test on workpiece. This is the key operation to protect it from being ruptured during welding rebuild

Question 2: How many welding pass to be made with hardfacing overlay on workpiece?

Answer: Normally we get Bottom Build, Buffer Layer, Enhance Milddle & Top Hardfacing Surface, total 4 overlays are recommended.

Question 3: How much hard from the surface of welding rebuilt parts?

Answer: The hardness tested from surface could be HRC60±2 .

Question 4: What is the warranty period of the rebuilt roller & grinding table of cement mill?

Answer: 2,000 hours guaranteed for slag and 8,000 hours for limestone in normal work condition.

Question 5: What kind of technology t aken on welding rebuilt products?

Answer: Open arc welding and Plasma transfer alloy weld ing.